Built on top of existing tank Cast-in-place concrete floor slab Sealed from tank below to prevent tank atmosphere into building Insulated concrete block walls. RoS 2S Disk Thickener Key benefits.

Gravity Belt Thickening Equipment To Thicken Primary Or Secondary Sludge By Bdp Industries

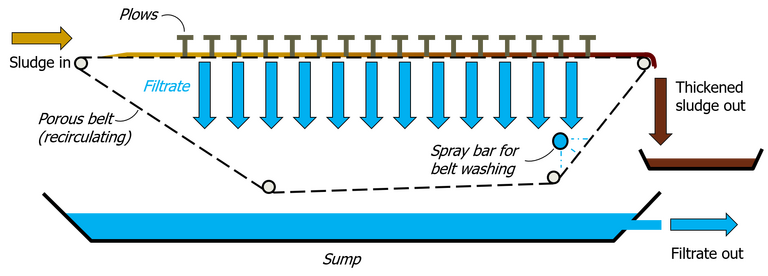

Gravity Belt Thickener GBT Andritz After the sludge is flocculated in the feeding pipe it enters the gravity zone where most of the liquids and solids are separated.

. Provide all the answers in thi ckener design and. A thickener operating with such an underflow velocity should have an underflow concentration Cu as shown. The principle of the GBT is.

For both designs the sludge enters the centre of a cylindrical tank and flows out to the periphery. PowerDrain belt thickener a very efficient technology for thickening prior to dewatering. This paper does not seek to.

Gravity thickening is the process by which biosolids are condensed to produce a concentrated solids product and a relatively solids-free supernatant. To assist solids transport gravity thickener bottoms are constructed with a floor slope between 16 and 13. Sludge is flocculated by the use of polymers introduced on the belt and the released water is drained through the gravity belt.

The dimensions are based on prediction of settling due to gravity alone. Except for small thickeners static and with hopper floo r these units have a system of very strong bottom scrapers. Applicability to wastewater treatment plants.

The PowerDrain gravity belt thickener is a highly efficient and economical solution for sludge thickening. The design involves selecting a typical solids flux and calculating the required surface area by dividing the anticipated solids feed by the flux 3. Patented design low investment costs low operating costs polymer power parts water.

It is the best technique if the Iaboratory data is available. Sepulveda Blvd Suite 1100. Fix a narrow strip of paper on one side of the container.

The process is simple the decrease in sludge volume is impressive. By material balance the underflow solids flux should be Gu as given by equation 3. 010 SD 015 SD 0 20SD 0 25SD 030SD Belt width 1m 15 m 2m 25m 3m Belt length 6m 6m 6m 6m Aqualitec Corp.

This technology is fitted with a stirrer comprising a series of relatively closely-spaced vertical arms and is therefore similar in appearance to a picket fence. Draw a line on the paper at the top of the pulp and mark 0 minutes. Typical test is done by using a 1000mL-graduated cylinder.

Thickeners are usually circular-shaped. 9735 NorthCross Center Suite A. This determines the free settling rate of the solids at the initial density.

A spreader plate ensures uniform distribution over the working width of the belt. Therefore replacing conventional gravity static thickener flotation sys tem. Ad Free Shipping Available.

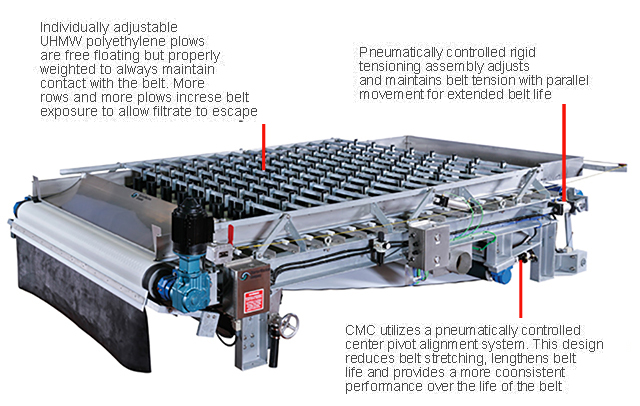

New Plow Design The Gravity Belt Thickener is used to thicken sludge prior to centrifuge or digestion processes. High unit capacity per floor space Low residence time eliminates septicity and float scum Superior thickening. A gravity thickener will be designed on the basis of hydraulic surface loading and solids loading.

Our Gravity Belt Thickener GBT reduce the volume of thin sludges and slurries produced during municipal or industrial wastewater treatment. Available Technologies Rotary Drum Thickener. The biosolids technology fact sheet for gravity thickening provides.

The feed is carried out through a pipe to a central hood serving as distribution and still area with a height that has no effect on compaction or compression bottom area. As a predewatering stage when combined inline with a Belt Filter Press. Area of the thickener.

Specially designed ploughs as well as the very large open area under the belt optimize the draining effect. New Plow Design The Gravity Belt Thickener is used to thicken sludge prior to centrifuge or digestion processes. A mix of primary or secondary sludge can easily be thickened to 7 wt pure secondary to over 5.

Gravity thickener designs usually include circular tanks 3-4 m 10-13 ft deep and up to 25 m 82 ft in diameter. Knock-out panel equipment removal. Gravity Belt Thickener.

Design based on Iaboratory data First Approach. The Gravity Belt Thickener OMEGA LD can be used. For five minutes at one-minute intervals mark the point to which the solids have settled.

As a final step to increase the sludge Dry Solids concentration to 68. Note that the rate varies between sludge types. A common variant on the gravity thickener design is the picket fence thickener.

ANDRITZ PowerDrain gravity belt thickener for efficient sludge treatment. Advantages and disadvantages of gravity thickening. High unit capacity per floor space Low residence time eliminates septicity and float scum Superior thickening.

The underflow operating line will betangential to the flux curve ifthe feed flux Gp is greater than Gu as is the case in Figure 1. The use of chemical additives lime or polyelectrolytes allows higher loading rates. A description of gravity thickening.

The OMEGA gravity belt thickener model should be selected to match the desired DS loading rate per hour and belt meter width. The design principles are to be the same as those for sedimentation tanks. Combine in the design contr ol and operation of a modern thick ener.

Gravity Belt Thickening to Increase Efficiency City of Elyria Wastewater Pollution Control Plant. Buy Gravity Belt Thickener on ebay. The gravity thickening design is similar to a clarifier.

A mix of primary or secondary sludge can easily be thickened to 7 wt pure secondary to over 5.

Gravity Belt Thickener Equipment Machinery Compositech Filters Manufacturer

Sludge Treatment Gravity Belt Thickening Sludge Processing

Gravity Belt Thickener Komline Sanderson

Gravity Belt Thickener Belt Filter Press Sludge Dewatering Charter Machine Company

Gravity Belt Thickener Komline Sanderson

Gravity Belt Thickening Equipment To Thicken Primary Or Secondary Sludge By Bdp Industries

0 comments

Post a Comment